22 Change of Volume with Respect to Pressure The change of a solid volume with respect to pressure can be related to the isothermal compress-ibility of the solid. Download Full PDF Package.

Pressure Vessel Software For Asme Viii Codeware

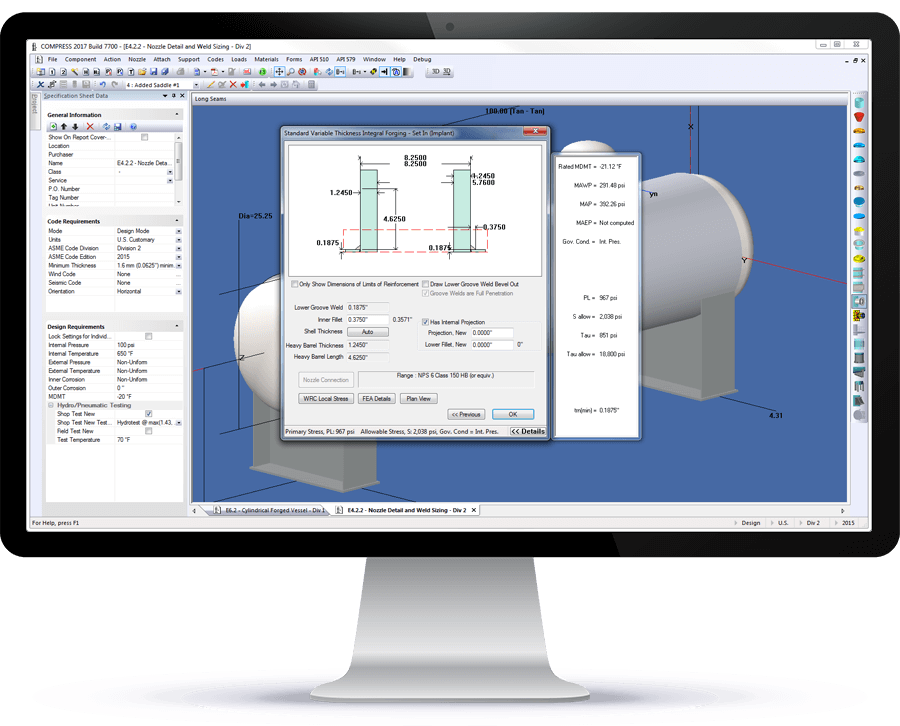

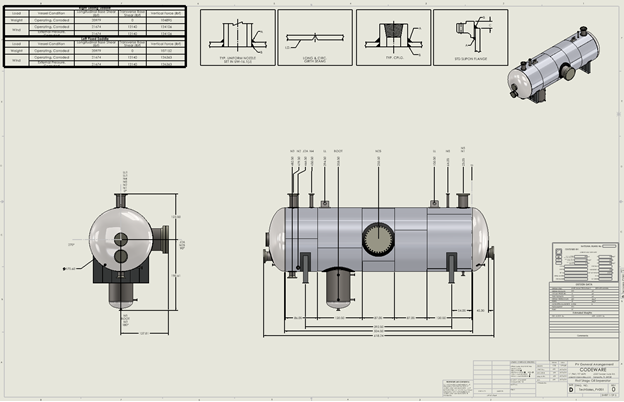

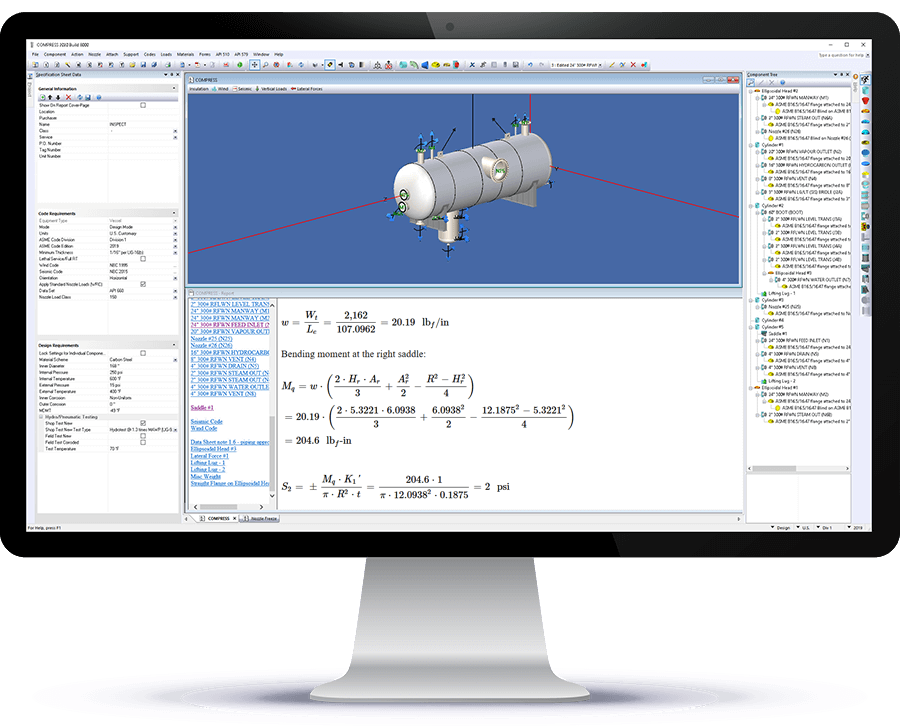

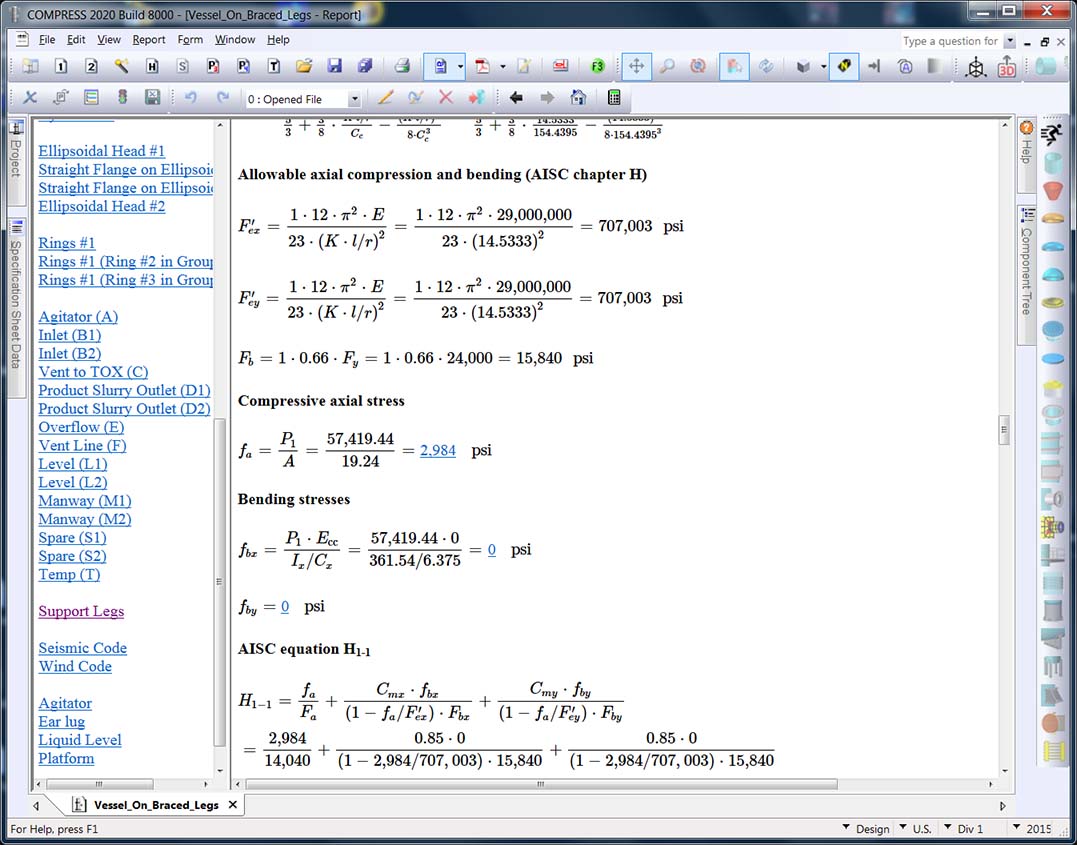

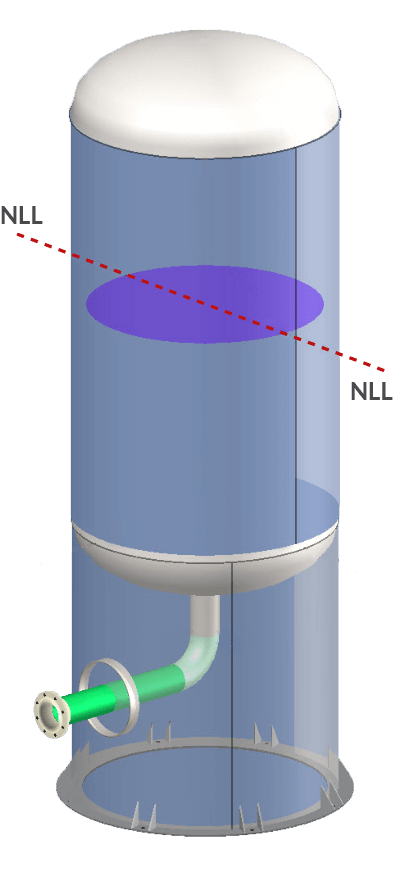

UG-37 Nozzle Designing Using COMPRESS One of the most involved tasks pressure vessel designers face is detailing nozzle openings to comply with ASME UG-37 UG-45 and UW-11.

. The pressure authorized on the. Stresses on pressure vessel nozzles and attachments have historically been checked using the Welding Research Council Bulletin 107. We use Compress PV Elite Design Calcs Nozzle Pro and our own in-house software.

Lifting Lug Design Spreadsheet Calculator. WALAS S Chemical Process Equipment Selection and Design. Pressure vessel design to ASME VIII-1 and VIII-2.

κ 1 V V P T 1 ρ ρ P T 1 ET 7. Instead the bulk modulus of elasticity is typically used. Pressure vessel Flange Check Design Spreadsheet Calculator per.

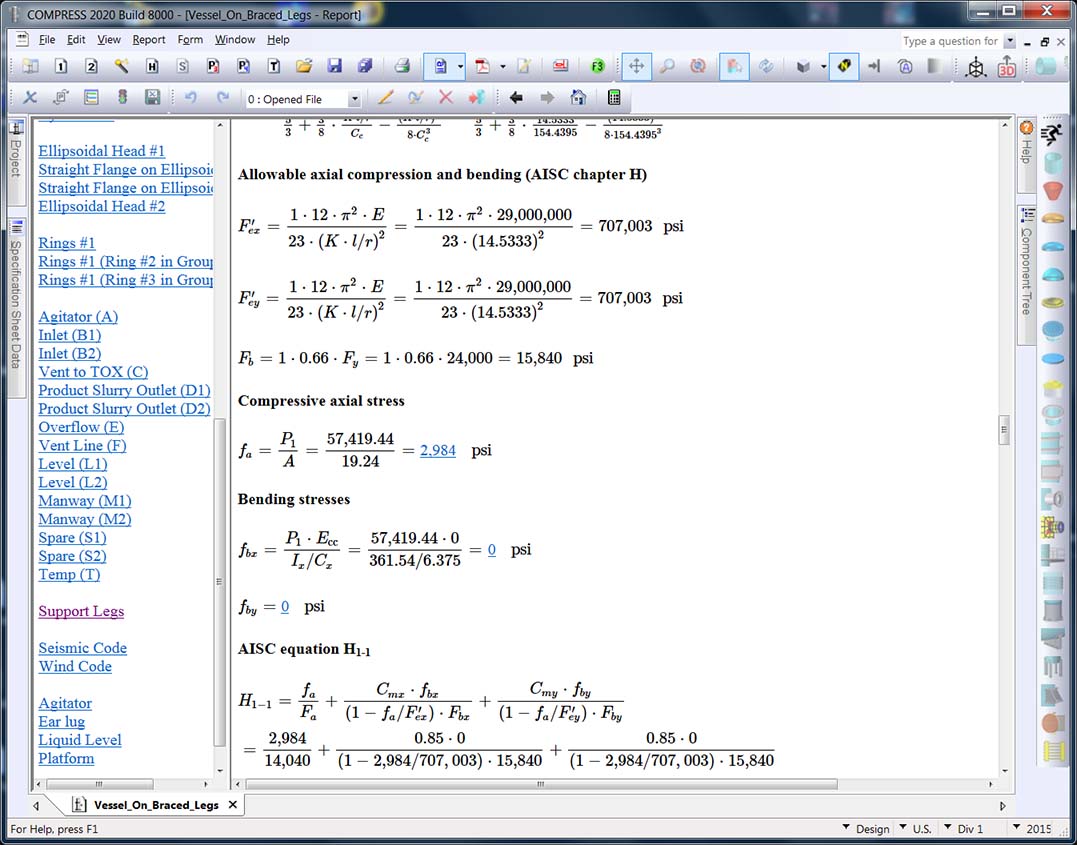

Nozzles serve many purposes including entry and exit points for process fluids inspection access and drainage. The isothermal compressibility κ is not used for solids. WRC 537 was published in 2010 and was meant to update and replace the widely used WRC 107.

In addition nozzles support other equipment such as piping. It is the basis for the pressure setting of the pressure relieving devices protecting the vessel. Whenever Pressure Vessel or Heat exchanger Static Equipment nozzle loads exceed the allowable values provided by Vendors Equipment manufacturer or standard project-specific tables guidelines the piping stress professional is permitted to use WRC 107 537297 or any other FEA to calculate the stresses at the Nozzle-Shell junction point and compare the.

1 TEMA 9th Edition. Full PDF Package Download Full PDF Package. WRC 537 contains equations that represent the graphs found in the March 1979 Revision of WRC 107 making it both easier to.

A short summary of this paper. 24 Full PDFs related to this paper. Cylindrical Shell Internal and External Pressure Vessel Spreadsheet Calculator.

Hot water heaters and boilers to ASME I and IV. The design pressure may be used in all cases in which calculations are not made to determine the value of the maximum allowable working pressure In the document AB-516 ABSA defines maximum allowable working pressure MAWP as. Collar Bolt Flange Pressure Vessel Spreadsheet Calculator.

Pressure Vessel Skirt Support for Vertical Column Design Spreadsheet Calculator. Coulson Richardsons Chemical Engineering Vol6 Chemical Engineering Design 4th Edition. ASME Section VIII Div.

Burst testing to multiple codes. Piping to B311 B313 B315 and others.

What S New In Compress 2020 Youtube

Pressure Vessel Software For Asme Viii Codeware

Pressure Vessel Software For Asme Viii Codeware

Pressure Vessel Software For Asme Viii Codeware

Compress Pressure Vessel Software Overview Youtube

0 comments

Post a Comment